The University of Michigan SmartSurfaces course is now complete. It was a collaborative, project-based learning experience in which undergraduate artists, designers, architects and engineers came together to build physical systems and structural surfaces that have the capability to adapt to information and environmental conditions.

The course was broken into two phases: an introductory / skill building phase, and the final project. For the first part of the course, participants focused on problem and constraint definition, structured brainstorming and skill building. Final teams were assigned in week six and the rest of the semester involved the production of the fully realized, funded projects shown below. Both phases focused on multidisciplinary, collaborative teams to carry out the assignments and projects. An important aspect of this course was the manner in which useful cross-fertilization emerged in the application of different disciplinary methodologies in response to concrete problems in practice.

Course participants had the opportunity to gain experience with using diverse tools and processes. Where possible, learning made use of practical problem solving through experimentation. All participants were challenged beyond their usual intellectual and disciplinary boundaries and had to negotiate and manage differences between the cultures of three university units (Art & Design, Architecture and Materials Science Engineering).

Each team was required to design, build, program and test a ‘heliotropic smartsurface’ that made use of:

• Solar energy harvesting

• Microcontroller programming (with Arduino) and circuit building

• Parametric modeling (with Digital Project)

• Digital fabrication

The teams had to consider and negotiate what makes a surface smart, and why we would be interested in a smart surface that follows the Sun. They had to engage a methodology of defining explicit relationships, complex behaviors, and unforeseen responses in a context of distributed authorship.

This is what they came up with:

The Shy Solar Array: An Adaptive Solar Array That Responds To Weather

Arrays of solar cells are vulnerable to their surroundings, do not maximize the sunlight-collecting surface area, and are unattractive. Inspired by the Mimosa Pudica plant and its tendency to shy away from external stimuli, our shy solar array was created. Our solar array protects itself from damaging elements such as snow or rain by flipping away from them. This will allow the solar array to be implemented in less than ideal weather locations, such as Michigan. Our solar array also maximizes the sun collecting surface area through its unique shape. The form of the array lends itself to a more efficient use of surface area by avoiding shadowing when the cell is rotated towards the sun. Also, the array stands out as a more desirable object that can serve as a stand-alone artifact as well as a useful solar array. Outside of the gallery this solar array would be implemented onto the rooftop of Michigan Engineering buildings as an alternative energy source. To further maximize the collected energy, the solar array should contain solar cells that are specially shaped to the design.

Team Fabric + Super J

Alyssa Ackerman – School of Art and Design

Johanna Brand – Taubman College of Architecture and Urban Planning

Yuming Jiang – Material Science and Engineering

Chris Johnson – Taubman College of Architecture and Urban Planning

Mat Schwartz - School of Art and Design

Michelle Svetkoff - Material Science and Engineering

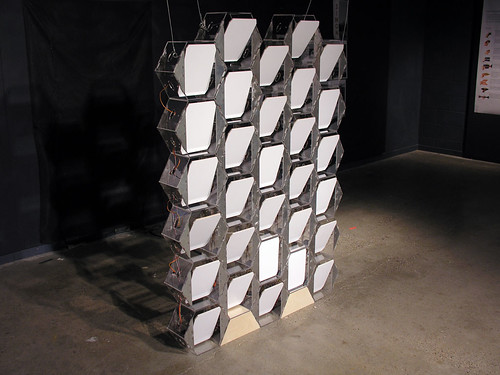

The iWall Modular Light-Filtration System

The wall you see here is a modular, scalable, self-adjusting multi-aperture window, designed to optimize light flow into a room by manipulating the position of rotating wood panels. You could call it an 'automatic venetian blind', as that is the gist of the purpose. The system consists of 30 individual modules, with one panel per module, which allow a variable amount of light to pass through. The structural elements are built modularly, but circuitry elements - such as wiring - are set up in a non-modular fashion. Individual module apertures open and close in reaction to the intensity of the light that passes through the wall as detected by light-dependent resistors (LDRs), seen on the projection side, holding a relatively constant light level on the ‘interior’ of the wall at all times - this gives 'heliotropic' and 'smart' characteristics to the wall - 'surface', fitting it into the premise of the SmartSurfaces course. The actual actuation is by a grid of servos powered externally and controlled through inputs from an Arduino Mega and the LDRs. The materials used in the assembly of the individual modules were 3/16" cast acrylic cut by laser and 3/16" 6061 aluminum sheet cut by water jet.

Team iWall

Westley Josiah Burger - Taubman College of Architecture and Urban Planning

Peter Hall - School of Art and Design

Brieana MacDonald - Taubman College of Architecture and Urban Planning

Michael Mathieu - Material Science and Engineering

Taylor McKenzie-Veal - School of Art and Design

Neil Poulin - Material Science and Engineering

Simon

Simon is a heliotropic, feel-good machine. He interacts with a user through motion and LED color mixing and enters a default solar-tracking mode when not in use. Face recognition technology, a simple joint system, and a flexible LED array make possible a wide range of movement and interaction while photovoltaic panels provide the power. By fusing emotional connections with the user, we hope to transform the concept of sustainability from a condition of sacrifice to that of pleasure.

Team Softcore

Rachel Boswell - School of Art and Designn

Eric Harman - School of Art and Design

Marc Maxey - Taubman College of Architecture and Urban Planning

Lindsey May - Taubman College of Architecture and Urban Planning

Damien Stonick - Material Science and Engineering

Zilin Wang - Material Science and Engineering

Exposure

Rather than using solar cells to convert sunlight into electrical energy, we are concerned with using the power of the sun in a more direct way. Exposure is a biological, heliotropic lighting system powered by photosynthesis. Living inside the piece are several Dinoflagellates, Pyrocystis fusiformis, aka bioluminescent algae. The bioluminescence of the organisms are set to a biological clock quite similar to our sleep cycle. During 12 hours of daylight Pyrocystis use the available light to photosynthesize, producing their own food and oxygen. At sunset the cells produce the chemicals that cause the luminescent reaction. If agitated during their 12-hour dark cycle, the algae give off a glowing blue light. In Exposure we have harvested several bioluminescent algae organisms, and embedded them into an architectural array. Within the array, varying panel heights correspond to the density of algae organisms contained in each unit. Infrared sensors located below the panels detect human presence, and trigger a motor. Attached to the motors, a cam makes contact with the panels creating enough motion to agitate the algae and expose their bioluminescent glow.

Team Slime

Ivan Adelson - Taubman College of Architecture and Urban Planning

Aidan Feldman - Computer Science Engineering & Department of Dance

Isaac Krauss - School of Art and Design

Laura Ligeski - Material Science and Engineering

Allison Sturm - School of Art and Design

David Theisz - Taubman College of Architecture and Urban Planning

The course will be offered again in Fall 2010.

3 comments:

Great to find out that Digital Fabrication is one of the foundamental branches of the course.

Keep up the great work.

The ponoko team.

0http://www.prokr.net/2016/09/swimming-pools-maintenance-cleaning-companies-9.html

http://www.prokr.net/2016/09/swimming-pools-maintenance-cleaning-companies-8.html

http://www.prokr.net/2016/09/swimming-pools-maintenance-cleaning-companies-7.html

http://www.prokr.net/2016/09/swimming-pools-maintenance-cleaning-companies-6.html

http://www.prokr.net/2016/09/swimming-pools-maintenance-cleaning-companies-5.html

http://www.prokr.net/2016/09/swimming-pools-maintenance-cleaning-companies-4.html

http://www.prokr.net/2016/09/swimming-pools-maintenance-cleaning-companies-3.html

http://www.prokr.net/2016/09/swimming-pools-maintenance-cleaning-companies-2.html

http://www.prokr.net/2016/09/swimming-pools-maintenance-cleaning-companies.html

Course participants had the opportunity to gain experience with using diverse tools and processes. Where possible, learning made use of practical problem solving through experimentation. All participants were challenged beyond their usual intellectual and disciplinary boundaries and had to negotiate and manage differences between the cultures of three university units (Art & Design, Architecture and Materials Science Engineering).

pakistani suits wholesale ,

wholesale salwar kameez catalogue with price ,

Post a Comment